West System Epoxy Mix Ratio

West system epoxy mix ratio. By Jim Derck. Acceptable ratio range by weight 484. 3We have now added Gflex Epoxy to the WEST SYSTEM product line.

Just like with WEST SYSTEM epoxy products an accurate mix ratio is extremely important for the resinhardener mix to cure. Be careful with mix ratio. Refer to page 4 for Directions for Use.

100mm Wide x 130mm High x 6mm Deep 78000mm 3. If you wish to blend one with another first mix on ratio the resin and hardener from one of our epoxies then add it to mixed on-ratio resin and hardener from another. Care should be taken when dispensing and mixing.

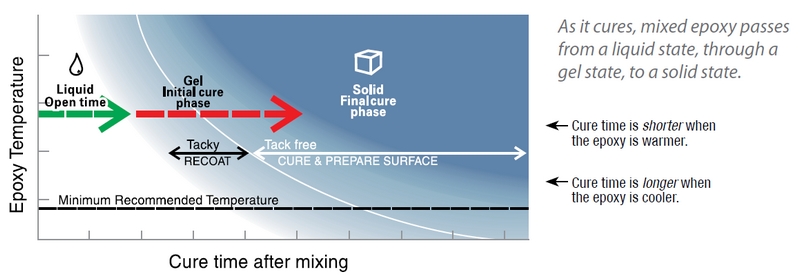

This will demonstrate the hardeners open time for the temperature you are working in and assure you that the resinhardener ratio is metered properly. These ratios are determined b the chemicals that make up both the resin and the catalyst and must be followed scrupulously. This will demonstrate the hardeners open time for the temperature you are working in and assure you that the resinhardener ratio is metered properly.

1 to 619 1. A fine black powder added to WEST SYSTEM epoxy 10 by volume to produce a low friction exterior coating with increased scuff resistance durability and mar resistant. If this is the first time you have used WEST SYSTEM epoxy begin mixing epoxy in a small test batch to get the feel for the mixing and curing process before applying the mixture to your project.

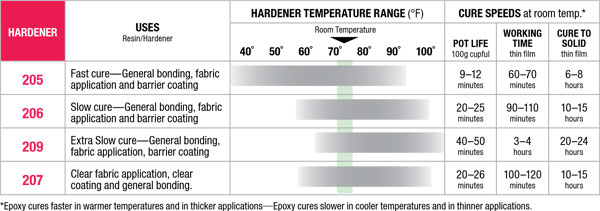

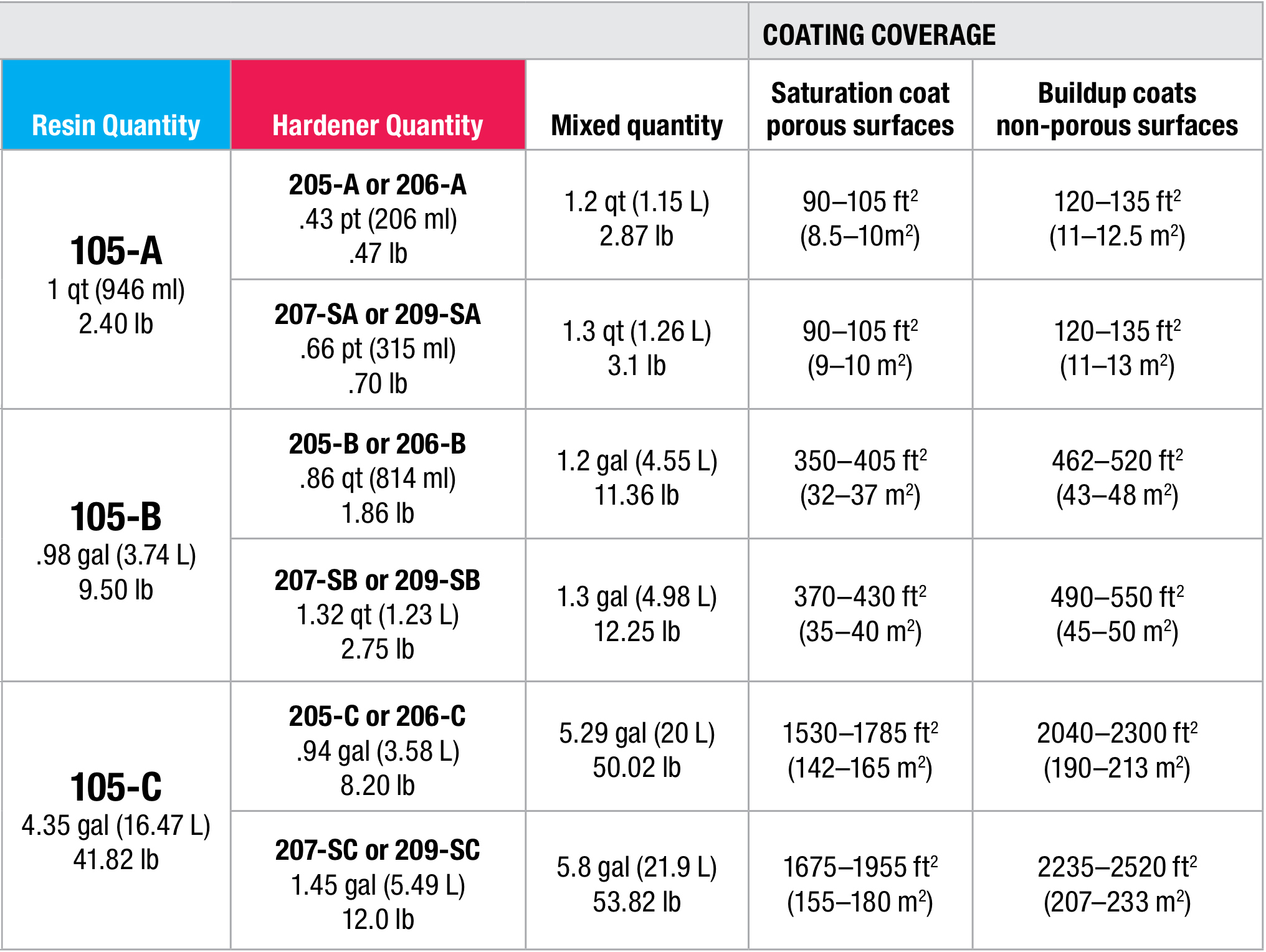

Perfect for West Systems mixing ratio 51 or 31 or Entropy Resins ratio of 21. Mix ratio information is on the hardener label and our technical data sheets. Capacity Epoxy Resin 946ml Slow Hardener 206ml.

WEST SYSTEM 105 Epoxy Resin and Hardeners make up a versatile epoxy system that can be used for everything from basic long-lasting repairs to the construction of high-performance composites. Dispense the proper proportion of resin hardener.

This will demonstrate the hardeners open time for the temperature you are working in and assure you that the resinhardener ratio is metered properly.

1 to 619 1. This will demonstrate the hardeners open time for the temperature you are working in and assure you that the resinhardener ratio is metered properly. Careful measuring of resin and hardener and thoroughly mixing epoxy are essential for a. If this is the first time you have used WEST SYSTEM epoxy begin with a small batch test to get the feel for the mixing and curing process before applying the mixture to your project. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new. WEST SYSTEM 105 Epoxy Resin and Hardeners make up a versatile epoxy system that can be used for everything from basic long-lasting repairs to the construction of high-performance composites. It is a clear pale yellow low-viscosity liquid epoxy resin. For optimal product utilization be sure to choose the same Size for both the resin and catalyst. 1 pump stroke of resin 1 pump stroke of hardener results in the proper mix ratio when using calibrated pumps.

The measuring Cup also has increments to add an epoxy thinner at either 10 or 20 of the mix depending on what degree of thinner is desired for a specific application. Do not attempt to control the cure time by altering the hardener ratio. Refer to page 4 for Directions for Use. Epoxy cures faster at higher temperatures and in thicker applications. Just like with WEST SYSTEM epoxy products an accurate mix ratio is extremely important for the resinhardener mix to cure. This will demonstrate the hardeners open time for the temperature you are working in and assure you that the resinhardener ratio is metered properly. Pumps make measuring the correct ratios of resin to hardener very easy.

Post a Comment for "West System Epoxy Mix Ratio"